Concreting Contractors

We Specialise In Concrete driveways Concrete walkways Airport Runways Carparks Pavements Aggregate Concrete Concrete curbing

Concreting Solutions

Concrete is a popular paving material as it is cheap to install and easy to maintain. If you are looking to lay concrete paving, contrete contractors to pave it for you, make a concrete base for a shed or garage, or do concrete footing for a new building, we are concreting specialists with long experience in concrete work.

From our offices in Reading, we cover all of Berkshire and surrounding areas. If you need concrete paving, there are types of concrete designs we offer, (below).

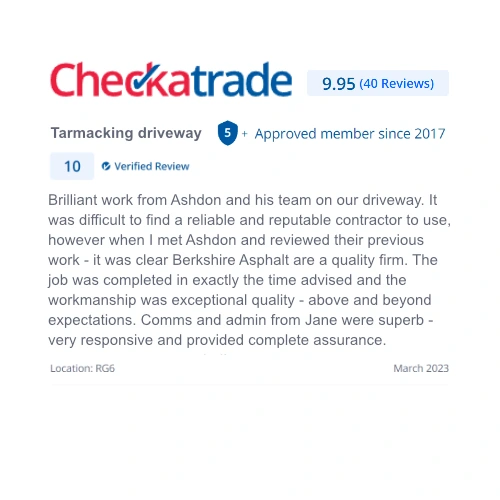

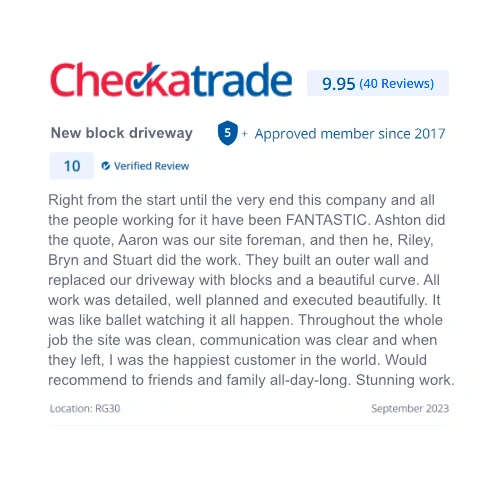

Highly rated & trusted professional Concrete company in Berkshire

Our last task is to ensure that the finishing has been properly done. All the surrounding ground that was upturned will be restored. We shall also do the required drainage systems. Our team is always dedicated to high quality of work to get you the best value for your money. Our main Concreting services we provide are:

We are a highly rated drainage company in Reading, Berkshire who provide many solutions for excavation and drainage throughout the area.

These are the most common concrete pavements as they are easy to make, affordable and reliable. They are unreinforced and have transverse joints that are spaced 5-6.5 feet. Some are made with dowels across the transverse joints. This helps in transferring weight loads. They are also made with tie bars across longitudinal joints for better interlocking between the slabs.

These pavements have joints and are reinforced with deformed steel or welded fabric wire. Joints spacing are further apart at 9-12 m than in the plain pavements. They also have dowels at the transverse joints and tie bars at the longitudinal joints. The reinforcement covers the whole cross-section of the pavement taking 0.15-0.25 % of the cross-sectional area. The reinforcement prevents cracking along the transverse.

Longitudinal reinforcement is better over joints in this type of pavement. The reinforcement covers 0.6-0.8% of the cross sectional area. The reinforcement is designed to keep cracks at a maximum spacing of 0.9-2.5 meters. These kinds of pavements are suitable for high traffic grounds like roads.

Once you have decided on concrete paving, we shall send an expert to the site to make a few assessments. Our contractors are open to your ideas and do as much as possible to make your ideas a reality so that the paving comes out just the way you want.

Depending on the nature of the ground, we can use either slipform or fixed form methods to lay the concrete. In fixed form, we have a machine that spreads, shapes, consolidates, screeds, and float finishes the concrete in one continuous operation. In fixed form method we use stationary metal forms to do all that.

We use materials from vetted suppliers so that the final concrete surface cures well without cracking and is able to withstand different weight loads. We can also stamp any decorative designs you have in mind.

After surfacing, our in concreters can keep repairs and pot hots to a minimal. If your existing concrete surfaces is becoming worn, damaged and cracking, our contractors can investigate the current cracks, damage or durability and provide a report with an effective affordable option for long term use.

Its common in the UK for private roads, lanes, dirt roads and pathways to become hazardous and undrivable on from the constant rain we get in Berkshire. A concrete contractor can come out to you to analyse the road, lane, pathway or dirt road and suggest the best way to turn it into a beautiful and useable surface. If you have a private road that needs concreting professionally, call us today.

For durable and reliable carpark surfaces, our concreting services extend to carpark installations and renovations throughout Reading and Berkshire. We specialise in designing and constructing concrete carpark spaces that withstand heavy UK vehicle traffic and adverse weather conditions. From standard small parking lots to multi-level carpark structures, our UK-based carpark concreting team uses high-quality surfacing machinery, workmanship and adherence to safety standards.

Berkshire Asphalt airport concreting is a popular service we offer, meeting the tight UK requirements of aviation facilities in the South East UK. Whether it’s airport runways, taxiways, aprons, or airport lanes in the airport area, our UK concreting contractors are ready to take the lead of you airport concreting projects up to very large scales. We understand durability and compliance with UK aviation regulations to provide the best solution that has the longevity and safety of airport surfaces in mind.

At Berkshire Asphalt, we cover various towns & areas throughout Berkshire. We are located in Reading, covering postal codes like RG1, RG2, RG30, RG31, RG4, RG5, RG6, RG7, and RG8. Bracknell, where you can find us with RG12 and RG42 postal codes. Maidenhead, we often provide work in SL6. In Windsor, SL4 is where we resurface many carparks, roads and driveways, while Slough benefits from our services in SL1 and SL2. Wokingham can count on Berkshire Asphalt with RG40 and RG41. Newbury is within our coverage area with RG14, and Thatcham with RG18. Ascot in SL5, Sandhurst with GU47, and Crowthorne with RG45. Further afield, our experts serve Hungerford with RG17, Woodley with RG5, Twyford with RG10, Sunninghill with SL5, Earley with RG6, Pangbourne with RG8, Cookham with SL6, Eton with SL4, and Burghfield with RG30.